CSR Initiatives

Creating value with communities

Our goals for "creating value with communities"

Develop a win-win relationship with society

Case examples

Participation in MATSURI -Developing microalgae-based bio paints-

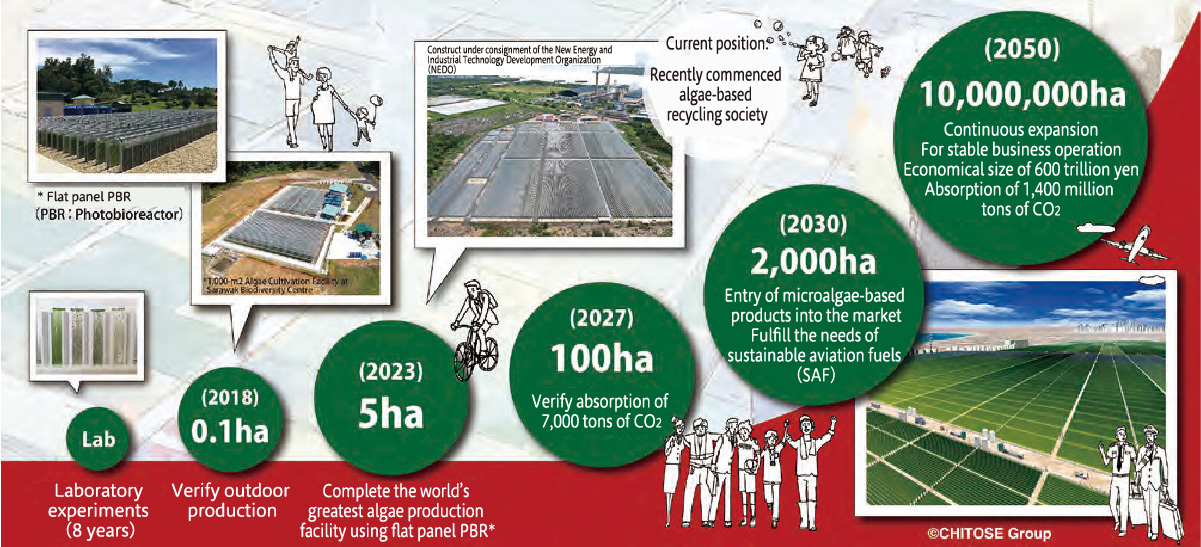

MATSURI is a Japanese cross-organizational collaborative project proposed by the CHITOSE Group (a family of biotechnology companies leading the global bio-economy) to develop a new microalgae industry. Algae can be categorized into large algae (such as seaweed) and microalgae. The CHITOSE Group started its activities in April 2021 with 20 partner companies to focus on the use of microalgae. We have been participating in their activities since then. MATSURI is an acronym for “MicroAlgae Towards SUstainable & Resilient Industry.” There are 79 partner companies currently taking part in this initiative.

We expect MATSURI to develop microalgae-based bio paints. We have already succeeded in developing plant-based bio paints, and microalgae are attractive raw materials because they store 10 times more oil than rapeseed oils.

Microalgae can be produced with less water than other plants and can be cultivated with just water and sunlight. It is possible to utilize deserted arable land, such as deserts and wastelands, to cultivate microalgae. We will soon enter an era where stable supply of food will become a great issue, it is advantageous to cultivate microalgae without worrying about competition with food production.

The goal of our group is to commercialize microalgae-based bio paints by 2025.

TBM Co., Ltd. -Co-creation of environmentally-friendly products-

LIMEX developed by TBM Co., Ltd. is a inorganic filler dispersed-type complex material made up of more than 50% inorganic materials (such as calcium carbonate). It has been patented in more than 40 countries and has been introduced at international meetings such as COP and G20. It was registered as an outstanding Japanese technology in STePP (Sustainable Technology Promotion Platform) of the United Nation Industrial Development Organization (UNIDO).

The primary raw material is limestone, which can be fully sourced in Japan (the main supplying country) and is one of the most abundant resources found on Earth. Limestones emits 58% fewer CO2 emissions of the same volume of typical plastics during incineration. Using limestone as replacement for plastics can suppress the consumption of fossil fuel-based plastics and reduce CO2 emissions during incineration. We are co-creating environmentally-friendly products by applying coating of our Bio Paint to cosmetic packages and construction materials that are molded by injection of polypropylene-based LIMEX.

TBM has also collected CO2 emitted from chemical plants and combined them with calcium ions of the steel slag (both byproducts of steel manufacturing by Greenore Limited). We have developed “Next generation LIMEX,” which uses Carbon Capture and Utilization (CCU) carbonate calcium as its primary raw material. This raw material is expected to achieve carbon negativity in terms of LCA. We will also be applying our Bio Paint to these Next generation LIMEX. We will also develop coating materials using CCU carbonate calcium.

We want to become the paint manufacturer of choice. To do so, we must leverage our unique technologies and products and create values with the community, leading and creating with others. We will work with other companies and industries with the same aspirations to become the paint manufacturer of choice.

Division General Manager