CSR Initiatives

Initiatives for environmental preservation

Our goals for "environmental preservation"

Scopes 1 and 2 by 2050 ②Achieve “Zero Emission” by 2030

*We define “Zero Emission” as “density of solid wastes that is less than 1%.”

Initiatives for environmental preservation

Each site is certified with their own ISO14001. The way the Environment Policy is applied at each site varies.

Below is an example of the Environment Policy at our site in Japan.

Environment Policy(Musashi Paint:Japan)

Environment Philosophy

Recognizing that Musashi Paint's business activities are closely related to the global environment as a whole, we will aim to be a "company that actively works to protect the global environment" by starting from the heart of each of us to respect nature and continuing with business activities that are friendly to the local and global environment.

Code of conduct

Status of our group’s ISO14001 certifications

Initiatives to achieve “Carbon Neutral”

Acknowledging the amount of CO2 emissions

The reason for global warming is said to be greenhouse gases (GHG), especially the increase in CO2 emissions. Our group is responsible to take initiatives against this issue.

We first started by acknowledging how much CO2 was emitted through our group’s business activities.

The following diagram represents how to categorize and calculate CO2 emissions.

While our group is located at many sites around the world, the data used to calculate these emissions are not globally unified. We first calculated emissions of our site in Japan based on the following method. We referenced the way of thinking and emission factors of the Ministry of the Environment and IDEA DB to determine the calculation method.

The following indicates the amount of CO2 emissions for each scope and category of our groups’ Japan site, determined using the aforementioned calculation methods.

In 2022, we were engaged in a facility investment project to construct a multi-tier warehouse, resulting in big numbers for Scope 3 Category 2 (capital goods and equipment investment). But our typical emission levels were close to the levels observed in 2023, which is why our total CO2 emissions decreased from 2022 to 2023.

When comparing Scopes 1 to 3 of our group, the ratio of Scope 3 Category 1 (raw materials) is significantly high.

Of Scopes 1 and 2, which efforts should be made on our own to reduce emission, most of our CO2 emissions are categorized as Scope 2 (use of electricity in our group).

Actual electric consumption and CO2 emissions at each of our production sites (2022)

The data on this table does not include electricity consumption or CO2 emissions by sales offices. 5,000 tons of CO2 are being emitted annually, caused by electricity consumption across the entire group.

Initiatives to reduce CO2 emissions

To reduce CO2 emissions from raw materials, we are shifting to raw materials with smaller emission factors to create products focusing on environment.

We also plan to reduce electricity consumption as a group-wide initiative. Electric energy is used in daily tasks performed by all employees.

This initiative to reduce electricity consumption is in sync with the management goals of FY2024.

We will be implementing the following measures to reduce our electric consumption.

We will also make effort to reduce CO2 emissions as indicated below.

Case examples of reducing CO2 emissions

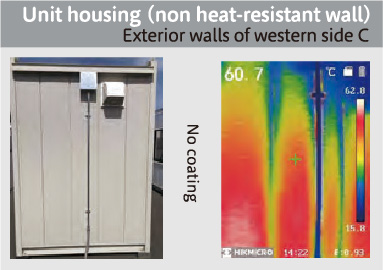

We used thermal-insulating and heat-resistant paints when re-coating the production tower at the Iruma factory.

Before coating

After coating

Since the actual coating was done in December 2023, we will not be able to confirm the effects until 2024. However, we performed preliminary experiments to verify the effects of the coating with these paints on prefabricated unit housings in the summer of 2023. If the same results are demonstrated, we can expect reduced electrical consumption and CO2 emissions.

■Verifying heat-resistant paints on unit housings

External wall surface temperature: 37.2℃

External wall surface temperature: 60.7℃

We implemented ECOMO to optimize transmission of electrical energy.

Cubicle facilities

ECOMO equipment (installed)

Tree-planting campaigns (Thailand, Vietnam, India)

Since we are unable to reduce CO2 emissions completely to zero, we must absorb some CO2 to achieve Carbon Neutrality.

Our group is taking initiatives such as planting trees, growing plants, and organizing facilities.

Tree-planting activity in an industrial park (Thailand)

Planting at our site (Ha Noi)

Tree-planting event (Ho Chi Minh)

Making room for plants (India)

Initiatives for waste-reduction

One of our management goals for 2023 was to reduce waste by 30% compared to the amount of wastes in 2022. We achieved our 2023 goal and reduced waste by 30% compared to the previous year.

Below are case examples of measures we took in Japan.

Reducing paint waste

We were able to reduce waste by mixing paint waste with solvent wastes to renew solvents.

Previously, paint waste was discarded as shown above

Sorting paint and packaging

Reducing solvent waste

With our new distillery, we were able to renew used solvents and reduce solvent waste.

Our new solvent distillery

Solvent waste

Cleaning solution after distillation

Reducing waste sludge

We were able to reduce booth cleaning operations and waste sludge with a new paint booth recycling filtration equipment.

Painting process

Paint booth

Paint booth recycling filtration equipment

Reducing plastic waste

Old color cards were donated to educational institutions, which reduced plastic waste.

Christmas artwork

Mobile phones

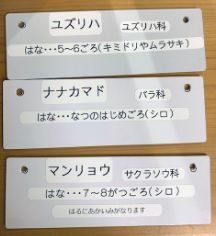

Wooden name plates

Reducing the amount of discarded scrap wood palettes and steel drums

Damaged wooden pallets were broken up, re-made into tables and benches, and sold on the internet. We also used small steel drums to store raw materials. We combined these with the wood from the pallets to remake them into stools to sell online.

Current state and challenges of waste reduction

At our group, we define waste as goods that do not have value. For example, emitted metals are NOT considered as wastes because they can be cashed. Separating waste allows us to reuse and recycle to save resources. At the Iruma factory, we separate waste into 17 categories. At overseas sites, it is often difficult to reuse and recycle no matter how we separate waste because there are no established means of treatment.

Waste is one of the major themes of environmental issues. In the future, it is likely that some common global framework will be established. We will monitor information regarding waste treatment at our sites to create “waste that could become resources.”

Case examples of environmental preservation measures at overseas sites

VOC treatment equipment (Suzhou, China)

We invested 9,200,000 Chinese yuan (approximately 190 million Japanese yen) at our site in Suzhou, China to install equipment to reduce VOC emissions.

The state government requested to meet the related personnel to share information about the initiative.

They were interviewed by a local TV broadcaster and their initiative was shared on the TV news.

At the presentation

Local TV news (actual broadcast)